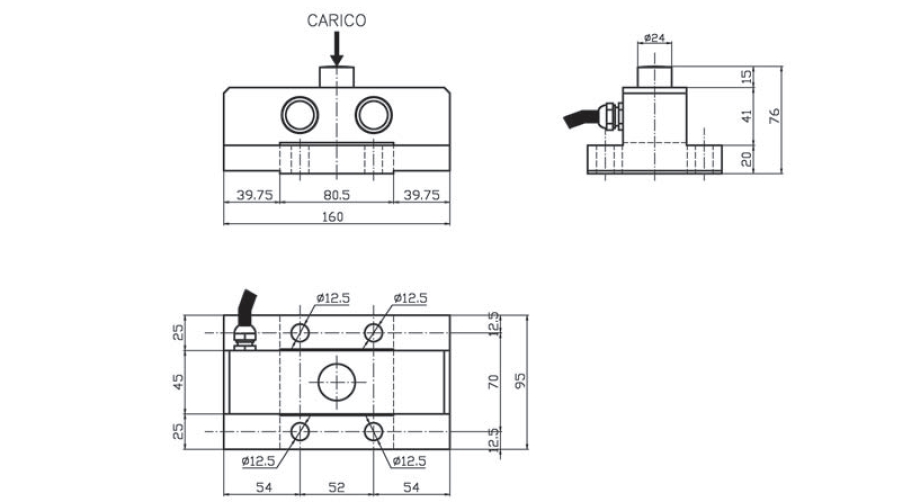

Double shear load cells for balances and scales, tension measure etc.

Double shear load cell

Upon request with ATEX or IECEx certification

C3 OIML Omologated

![]() Click to enlarge image

Click to enlarge image

| Material | Steel |

| Nominal load | 5, 10, 15, 20, 25, 30, 35 t |

| Limit load | 150 % F.S. |

| Breaking load | 300 % F.S. |

| Supply voltage | Maximum 15 V dc |

| Output | 2 mV/V |

| Output tollerance | 0,1 % F.S. |

| Zero tollerance | 1 % F.S. |

| Linearity | 0,03 % F.S. |

| Hysteresis | 0,03 % F.S. |

| Reapeatability | 0,03 % F.S. |

| Input resistance | 700-710 ohm |

| Output resistance | 700-702 ohm |

| Insulation resistance | >= 2000 Mohm |

| Creep (30 Minutes) | 0,03 % F.S. |

| Thermal compensation | -10 / +40°C (14 / +104°F) |

| Operating temperature | -20 / +70°C (-4 / +158°F) |

| Temperature deviation zero | 0,003 % F.S. / °C |

| Temperature deviation full scale | 0,002 % F.S. / °C |

| Protection class | IP 68 |

| Standard cable length | 16 - 20 m – 6 x 0,30 (shield not connected to the load cell body) |

| Type | SHIELDED CABLE 6C R6 PVC 6X0,30 |

| Length | 16 - 20 m (body lead cell not connected shield) |

| Red | + IN |

| Black | - IN |

| Yellow | + REF |

| Blue | - REF |

| Green | + OUT |

| White | - OUT |

General precautions to be followed in the installation and assembly of load cells: